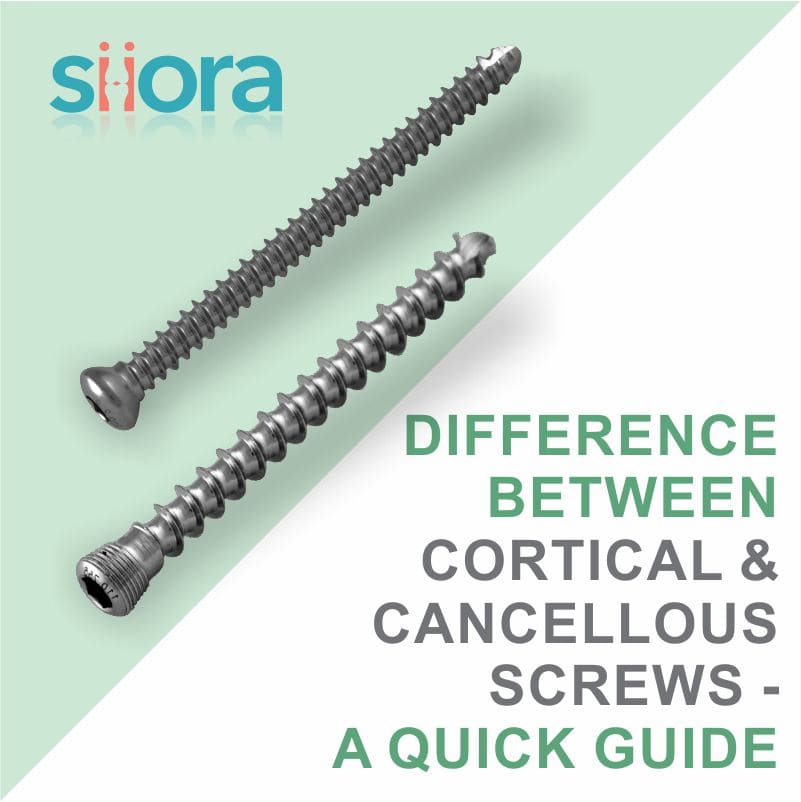

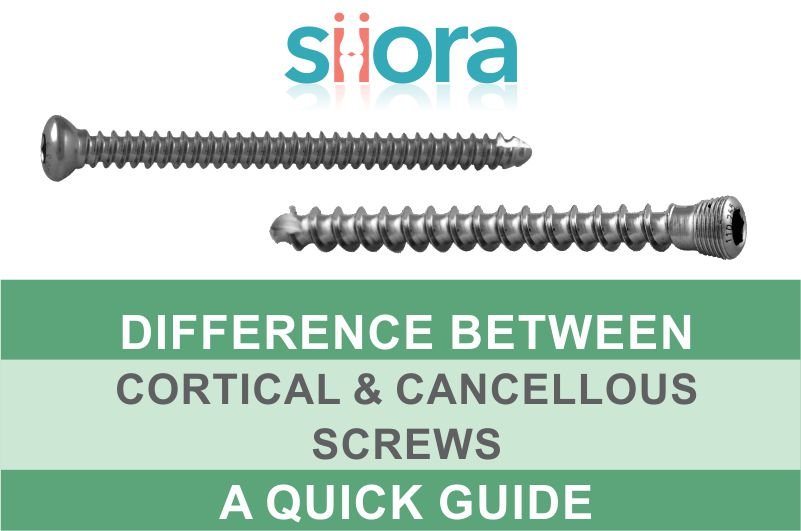

Orthopedic screws play an important role in the open reduction and internal fixation of fractures. They are used for fixing orthopedic plates and fractured bone fragments to allow the fracture to heal. Different types of orthopedic screws are there including cancellous screws and cortical screws which are used depending on the type and location of the fracture.

In this post, we will have a look at the difference between cortical and cancellous screws along with their structural anatomies and when they are used. Let us start with a brief introduction to cancellous screws.

What is the Difference Between Cortical and Cancellous Screws?

Before talking about the difference, let us have a brief look at what orthopedic screws are.

An orthopedic screw is a general term for screws that orthopedic surgeons use for fixing different orthopedic conditions including fractures, non-unions, and malunions. Orthopedic screws are similar to other mechanical screws with a similar function i.e., to provide compression and stability, here fractures. When screws are applied, broken bone fragments are pressed against each other to allow proper fracture healing. Let us see what cortical and cancellous are:

What Are Cancellous Screws?

Cancellous screws are the type of orthopedic bone screws that orthopedic surgeons use for fixing fractures in metaphyseal bones. In other words, cancellous screws are for the surgical fixation of fractures in the cancellous bone.

Cancellous bones form the ends (epiphyses) of long bones. This type of bone is spongy, light, and porous bone having large spaces in between giving it a spongy appearance. Cancellous bone is also known as trabecular or spongy bone.

If we talk about the structural configuration of cancellous screws, then they are designed to have a coarse pitch. These screws are ideal for optimizing fixation in metaphysical bone environments. They are also the best for producing interfragmentary compression in joint areas, for example, tibia head fractures.

As per the research, cancellous screws are biomechanically advantageous over cortical screws, especially when surgeons apply them to the metaphyseal bone. Hence, they achieve better compression with excellent displacement resistance at the screw-plate interface. Cancellous screws have a large thread diameter to core diameter ratio which makes them suitable for providing compression and anchoring in soft cancellous bone.

What Are Cortical Screws?

As the name suggests, a cortical screw is designed to fix fractures in the cortical bones. In other words, we can say that cortical screws are for fixing fractures that occur along the shaft of the bones. They are among the commonly used screws in orthopedic surgeries.

Cortical bone has a protective layer over its internal cavity. Around 80% of bone in the human skeleton is cortical bone. Hence, a cortical screw is the choice of orthopedic surgeons for fixing most fractures. This bone possesses high resistance to bending and torsion, as a result, is able to bear the weight of the body. A cortical screw can also affix implant plates or other orthopedic devices onto the cortical bone.

Cortical screws have a fine pitch. This means they possess a larger number of threads when compared to cancellous screws. They have a lower thread diameter to core diameter ratio. This structural anatomy makes cortical screws suitable for anchoring inside the dense/compact cortical bone.

What Are the Different Types of Orthopedic Screws?

We hope that it must have been clear by now about the basic difference between cortical and cancellous screws. Now, these screws are further classified into different types based on their function and structure. We can broadly classify these screws as:

Self-tapping screws

As the name suggests, self-tapping screws do not require a pilot hole during insertion. These screws will tap their holes when applied to the bone. Self-tapping screws have “flute” tips that help them cut their threads.

Non-self-tapping screws

As the name suggests, these screws will require a pilot hole before insertion.

Locking screws

Locking screws have a threaded head profile. This means they are made having threads on their heads that help them lock into locking plates and provide a fixed-angle construct.

Non-locking Screws

Non-locking screws are used with non-locking plates. They have plain heads without any threads.

Fully threaded

Fully threaded screws have threads along their complete shaft. This means threads in the screws start right below the head and end at the tip.

Partially threaded

Partially threaded screws have plain shafts halfway along the length of the screws and are threaded afterward until their tip.

What Materials Are Used for Manufacturing Cortical and Cancellous Screws?

Orthopedic screws like cortical and cancellous screws are made of medical-grade metal alloys namely stainless steel and titanium. Here are the raw materials:

Stainless Steel

It is a common raw material that is used for manufacturing both cortical and cancellous screws. Stainless steel-made screws are more commonly used.

Titanium

Titanium is always the best when it comes to manufacturing orthopedic screws. However, they are expensive when compared to stainless-steel screws. They are lighter in weight and have lesser chances of infection.

Siora Surgicals is a trusted name in orthopedic implants manufacturing and supplying industry. It is a seasoned player when it comes to fabricating an international standard range of orthopedic screws and other trauma implants. The company uses medical-grade stainless steel and titanium to manufacture implants and tests them against stringent quality parameters before approving fit for use. Having served more than 30 years in the industry, Siora is also known as an experienced OEM/contract manufacturing service provider across the globe. Moreover, the company is also known to be a regular participant at various healthcare conferences. This year, Siora will exhibit at the global Arab Health 2025 Expo in Dubai. Attendees can explore Siora’s advanced and new collection of orthopedic implants at booth MS.C05.